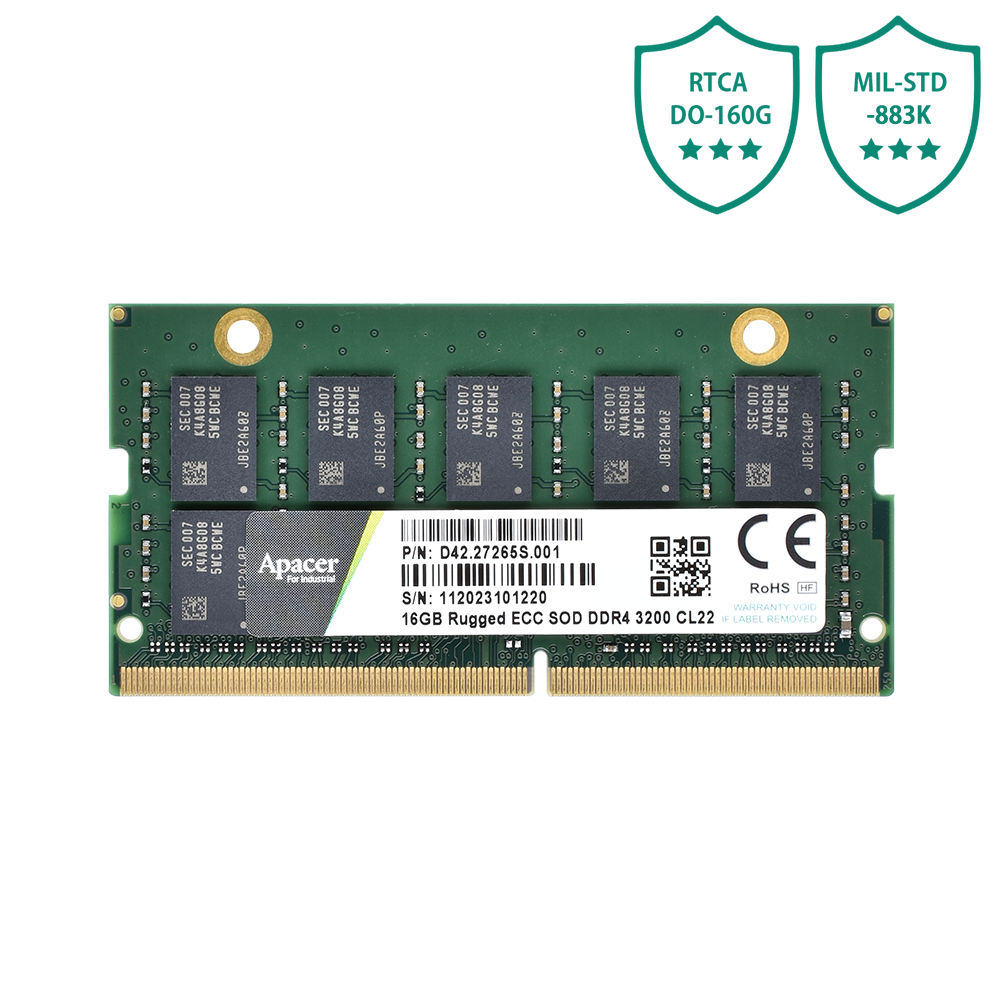

Apacer's world's first patented anti-sulfuration memory modules and anti-sulfuration SSDs with the industry's highest level of anti-corrosion certification can meet the needs of industrial products facing harsh environments.

Unlike the relatively stable application environment of standard computers, industrial computers often need to operate in high-temperature or highly polluted environments. In the face of environmental and air pollution caused by industrial and local emissions, electronic components exposed to high temperature, high humidity and highly polluted environments for a long time are prone to corrosion or even creep corrosion sulfuration, which leads to shortened lifespans and unexpected failures. |

|

|

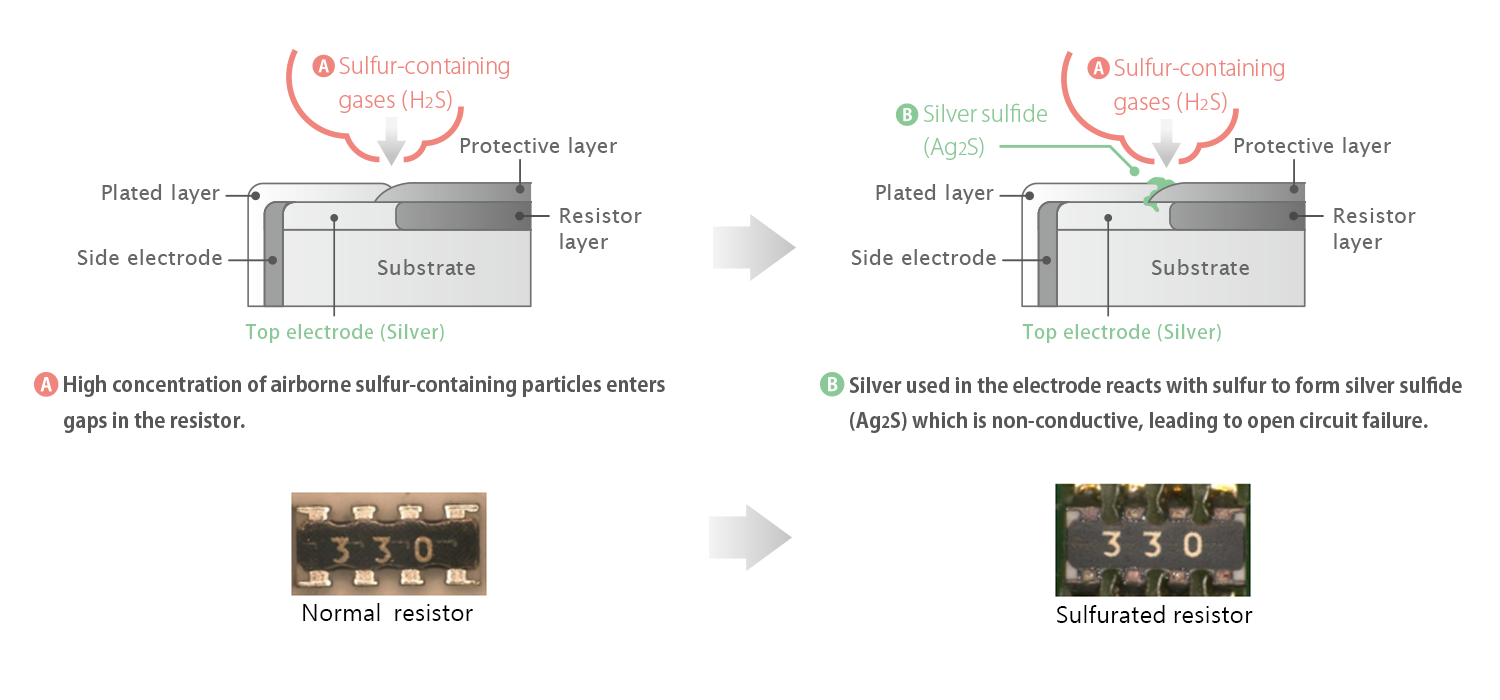

Certain areas of the world and certain manufacturing processes are prone to developing excessive concentrations of hydrogen sulfide and sulfur dioxide in the air. These can easily combine with the silver material of an electrode layer, producing silver sulfide and causing an increase in resistance. In some cases, a buildup of silver sulfide can lead to an open circuit and failure of the device. In other cases, these gases can exert a corrosive effect on electronic components containing copper, affecting the reliability of the product.

|

|

|

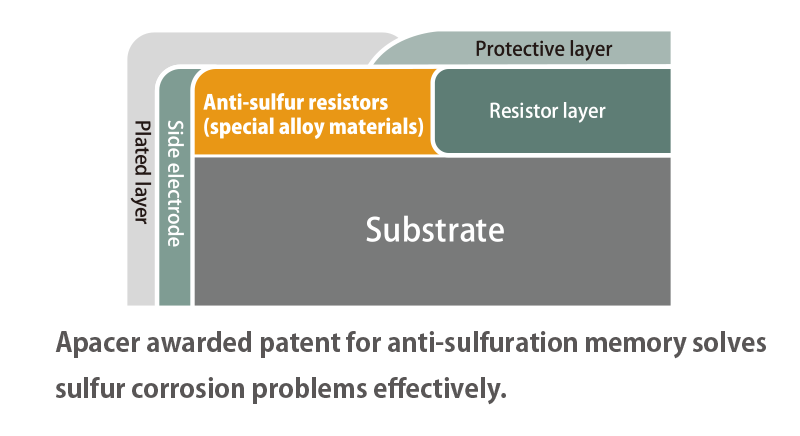

With the issue of sulfuration in industrial environment in mind, Apacer has developed the world’s first range of anti-sulfuration memory modules. |

|

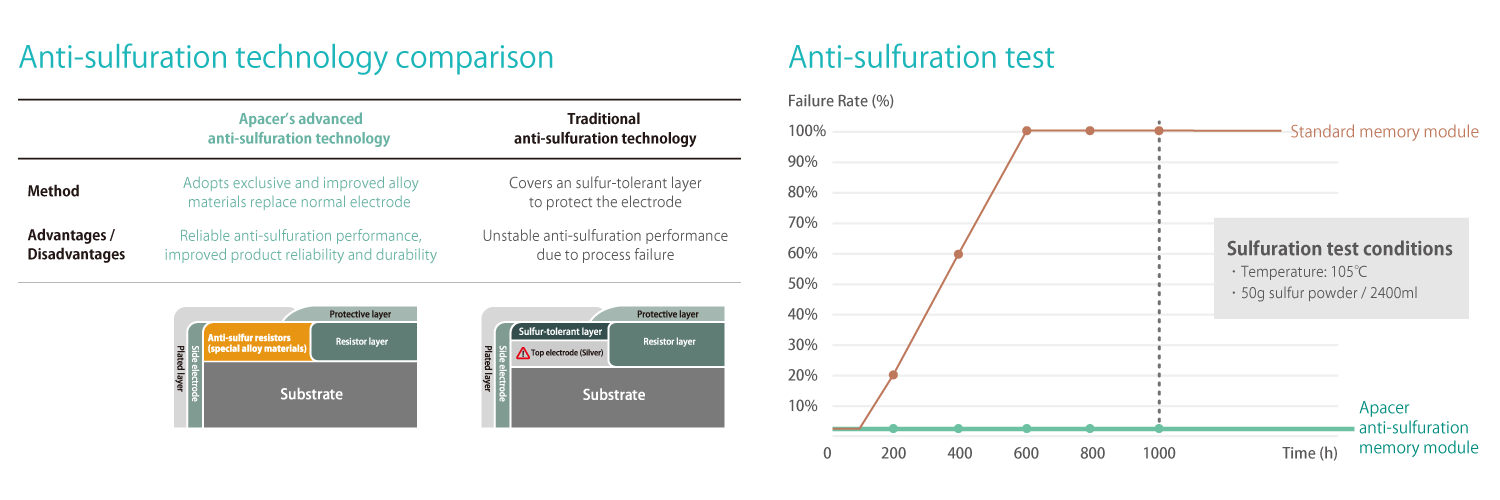

The most common anti-sulfuration method is to cover an sulfur-tolerant layer to protect the electrode, which prevents silver from reacting with sulfur-containing gases and increases sulfur tolerance of the electrode. However, the anti-sulfuration performance of this method is rather unstable due to process failure, such as layer shift or layer failure. |

|

|

|

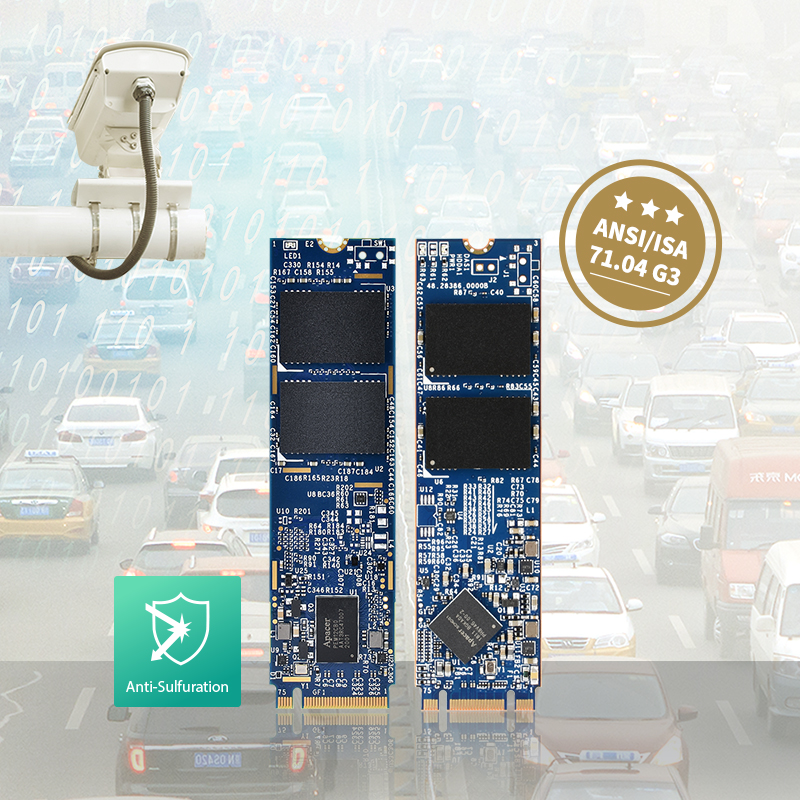

In order to reduce the impact of pollutants in the air on the proper operation of information equipment, many large data centers have not only begun to strictly implement environmental controls. One popular standard for air quality is the 71.04-2013 G1 standard defined by ANSI/ISA. Apacer's anti-sulfuration SSDs achieve a complete air barrier through strict inspection of special materials and technologies. After two complete accelerated verification tests of MFG (Mixed Fluid Gas and FoS (Flower of Sulfur), it has passed the American National Standards Institute/International Association of Automation 71.04 G3 air corrosion certification. This proves that it has reached the industry's highest level of sulfur resistance, including resistance to silver corrosion, copper corrosion and creep. |

|

|

|

Industrial applications |

.png) |

|

|

Value-added technologies for extreme environments: Multiple protections and improved reliability |

.png)

|

Conformal coating on the printed circuit board not only protects against humidity, dust and contaminants, increasing the components' durability and corrosion resistance, but also provides a second layer of protection for products in extremely harsh environments. |

|

.png)

|

The gold finger specifically designed for the anti-sulfuration memory modules is 30µ thick. Not only does the extra thickness offer wear resistance and durability for repetitive plugging/unplugging, it also improves anti-sulfuration, allowing for more stable signal transmission. |

|

|

As high temperature accelerates sulfuration of resistors and in turn shortens product lifespan, Apacer combines anti-sulfuration with wide temperature support to ensure stable operation even in highly polluted sulfur-rich environments and extreme climatic conditions. |

|