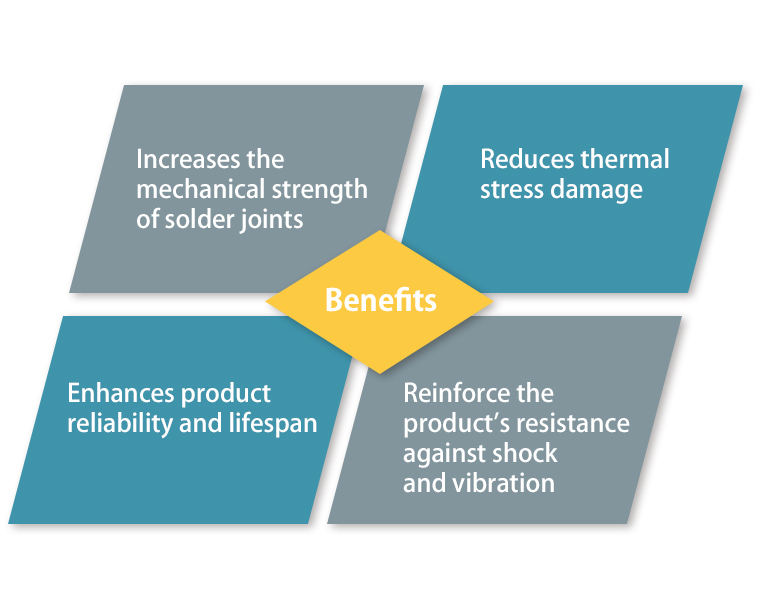

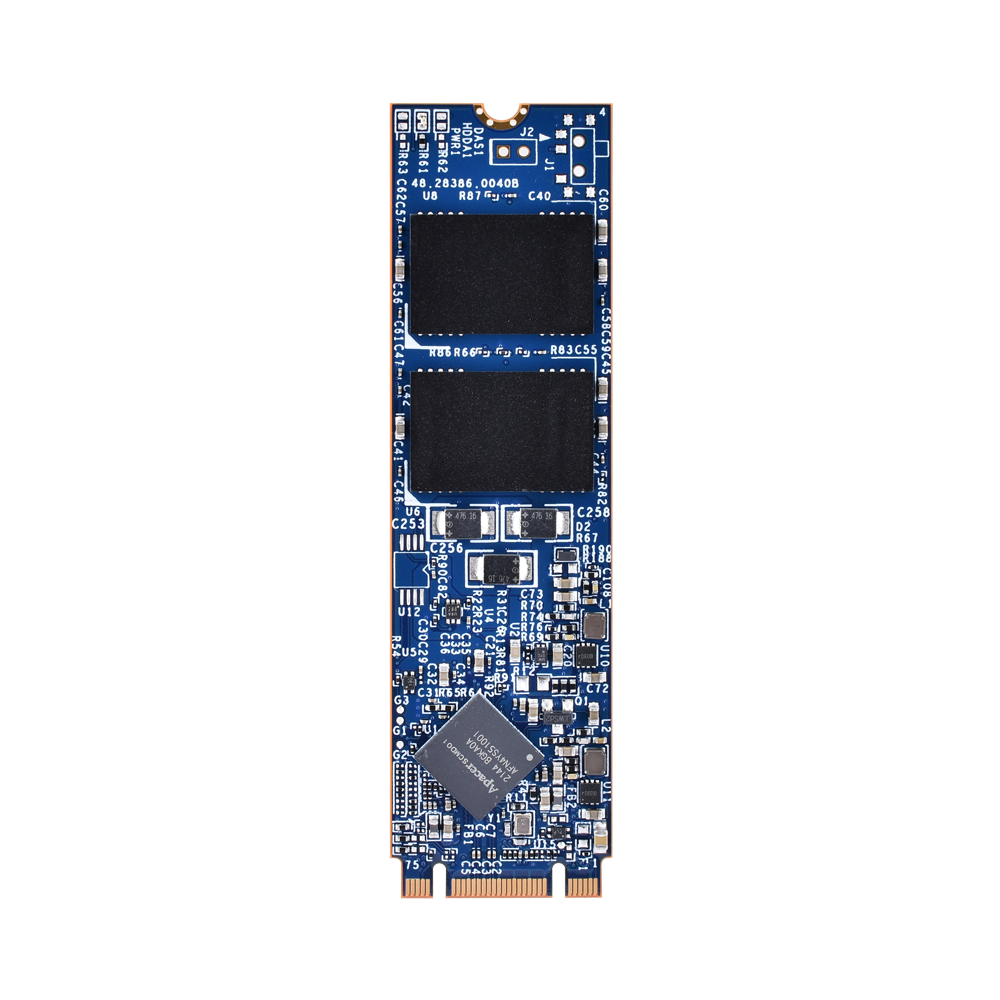

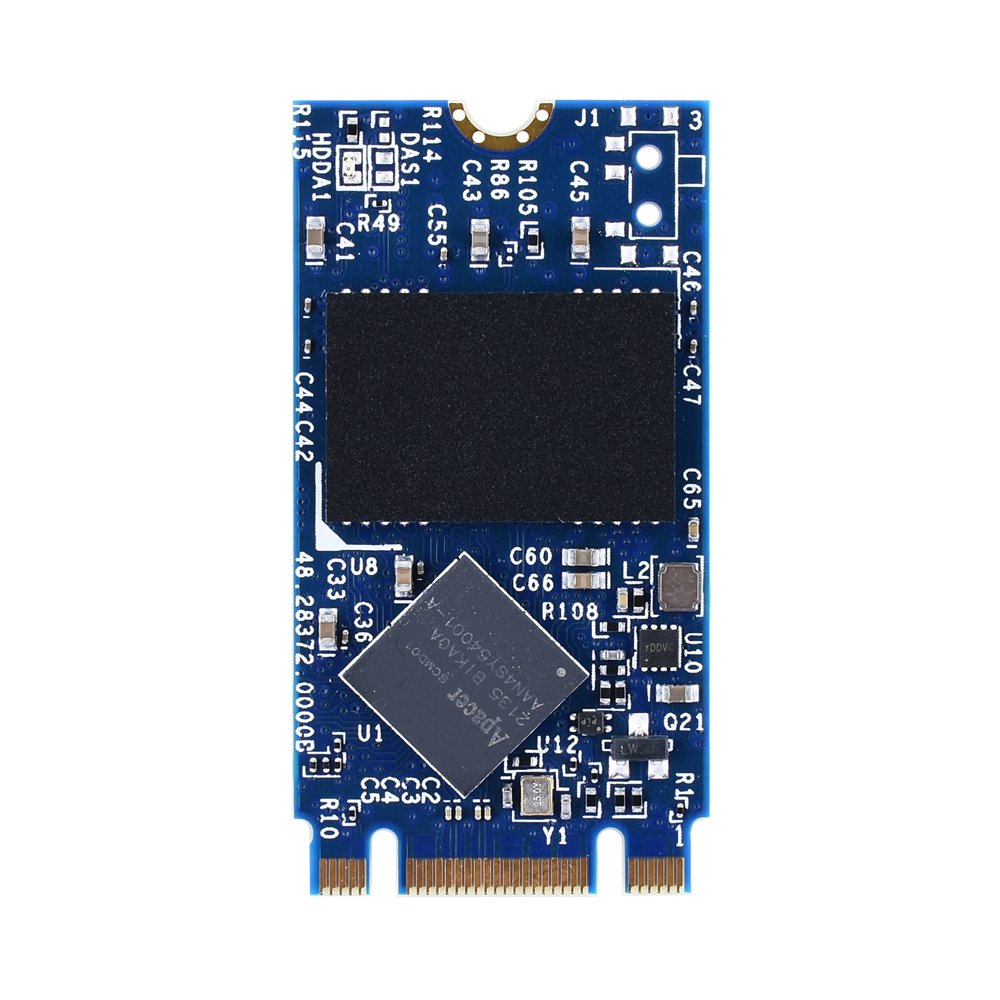

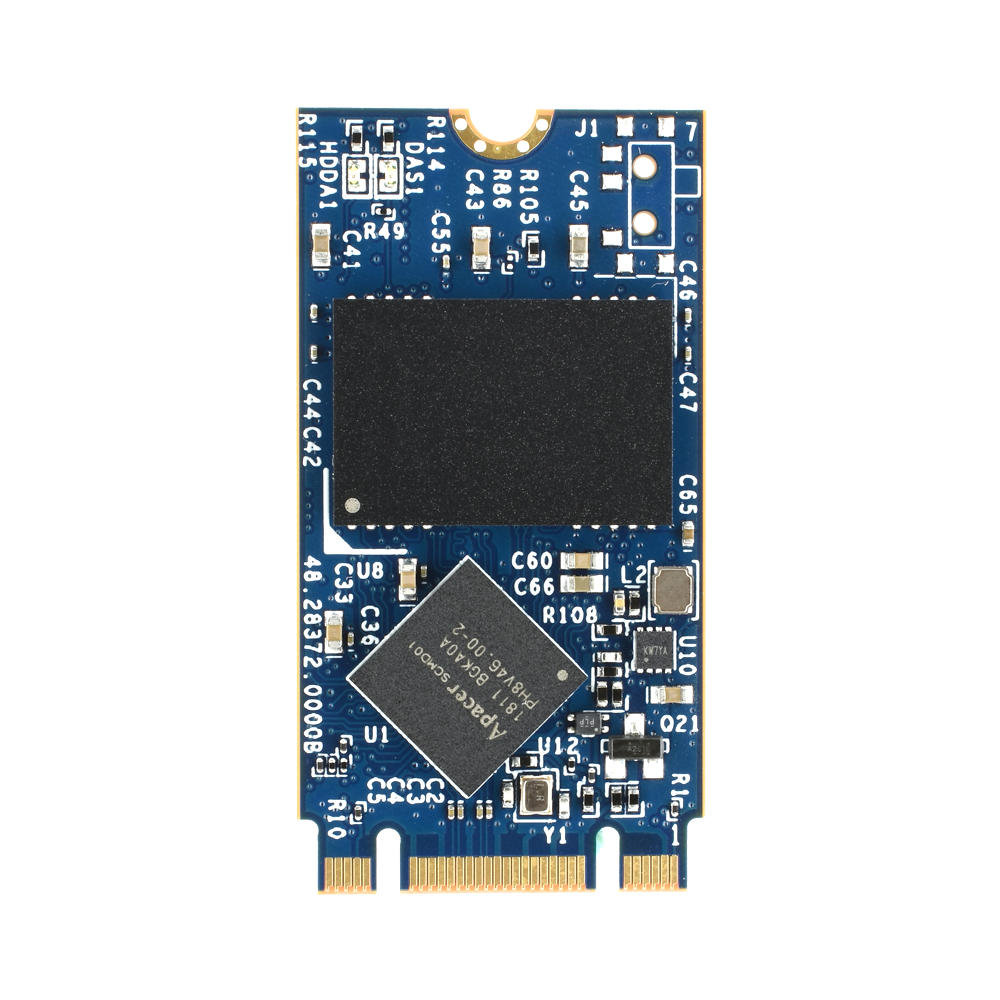

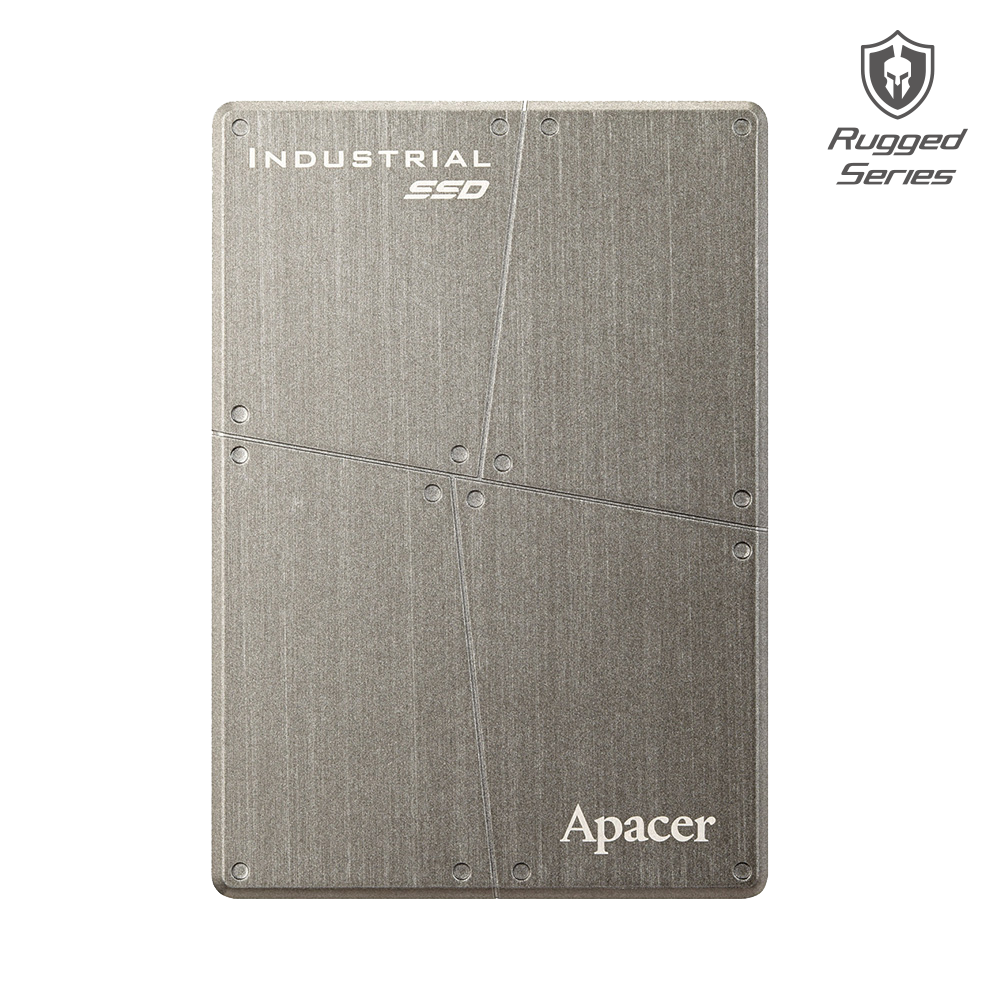

Apacer’s Sidefill technology strengthens the connections between solder joints and their board, making them more robust and vibration-resistant. It also allows for heat dissipation to offset thermal damage.

As PCBs become smaller, so too do their solder joints. Unfortunately, this puts the joints under greater vibrational and thermal stress. To counteract this phenomenon, Apacer offers Sidefill technology. This is a cost-effective solution to these issues, as Sidefill strengthens the connections between the solder joints and their board, making them more robust as well as more vibration-resistant. It also allows for heat dissipation to offset thermal damage. The designer of any module destined to work in harsh environments should consider Sidefill as an option. |

|

|

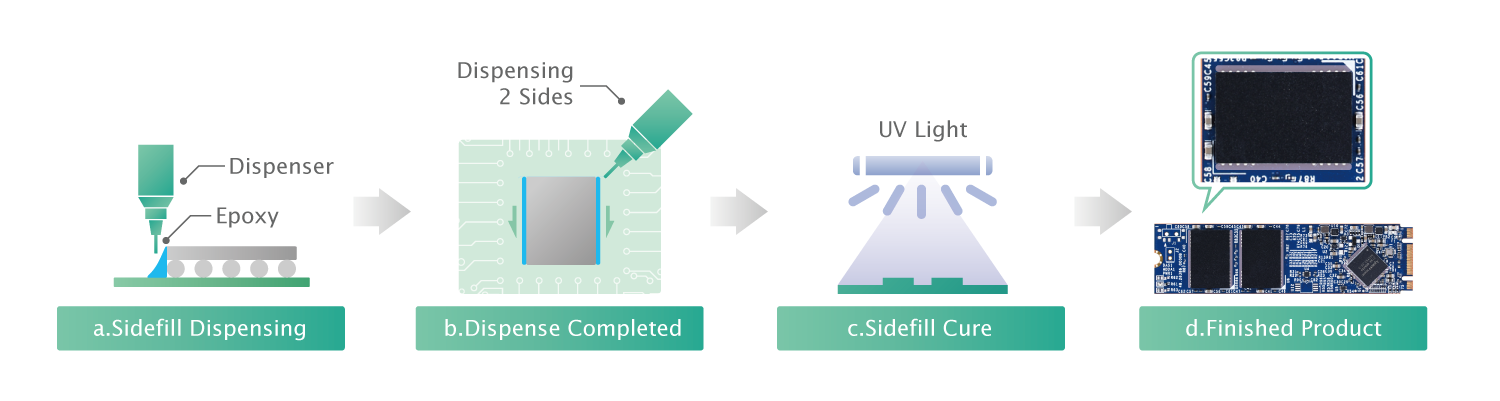

Sidefill Flow

Epoxy is usually used as the Sidefill. It is dispensed along the edges of the chip. The substrate is then dried by UV light to increase the mechanical strength of the solder joints and reinforce the product’s shock resistance. |

|

|

Apacer provides Sidefill technology to increase product reliability and resistance to various thermal and mechanical shocks, ensuring that products continue to operate normally in high vibration and under extreme environmental changes. It’s an ideal solution for industrial equipment, such as that used in defense technology, vehicles, outdoor applications and rugged computers |

|

-

New

SSD

PV250-M280

-

New

SSD

PV230-M280 (M Key)

-

New

SSD

PV230-M280 (B+M Key)

-

New

SSD

PV230-M242 (M Key)

-

New

SSD

PV230-M242 (B+M Key)

-

New

SSD

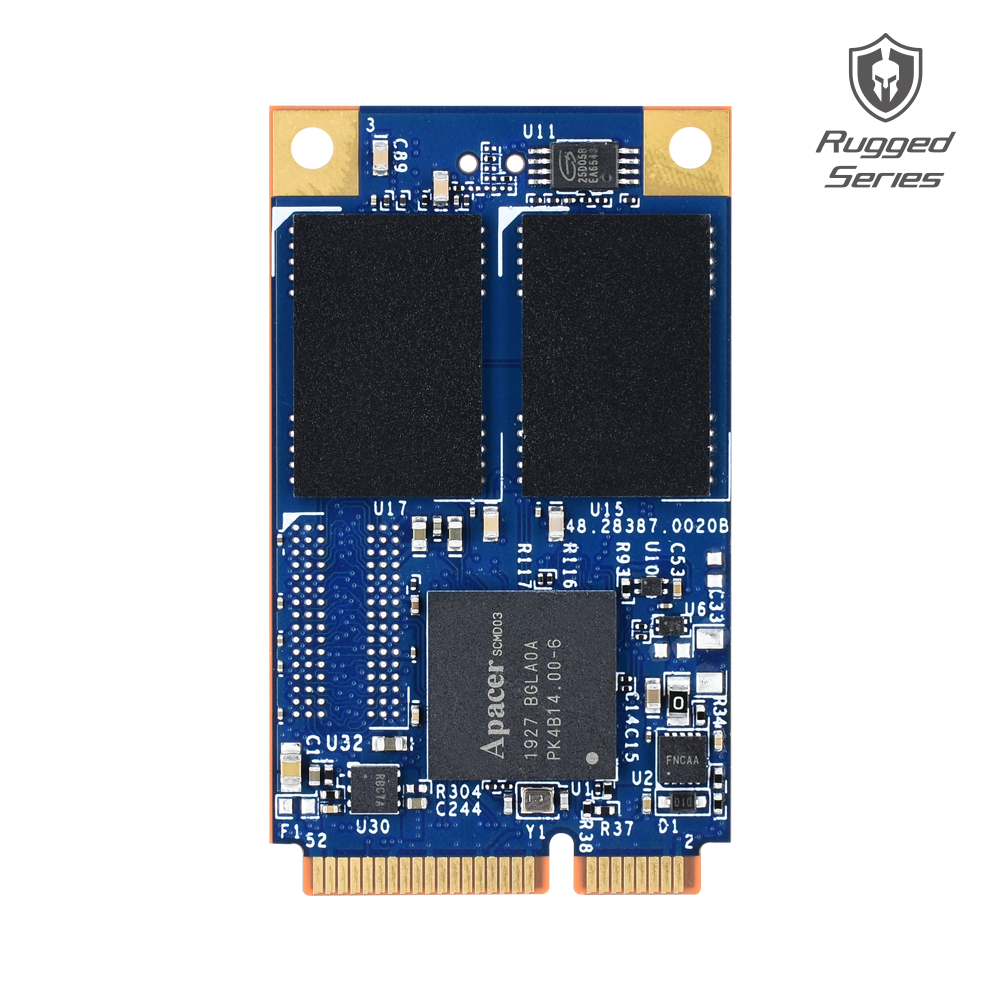

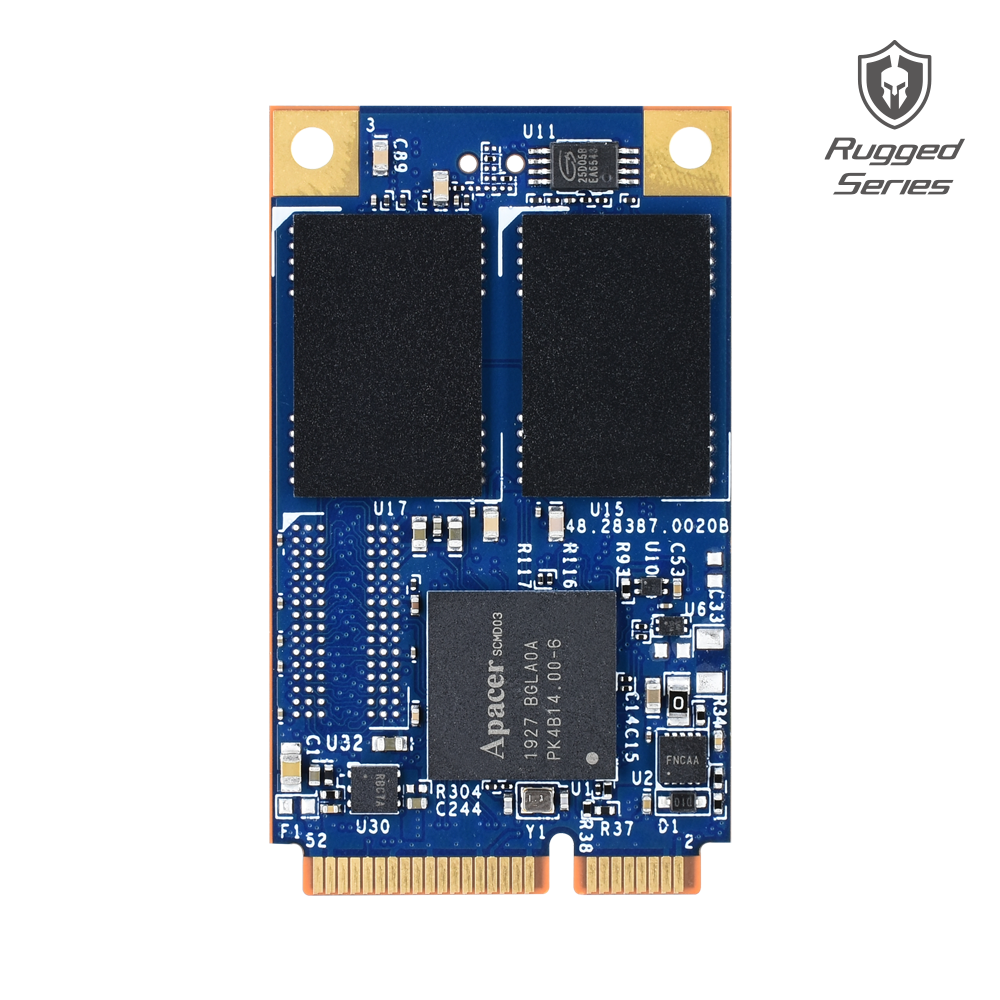

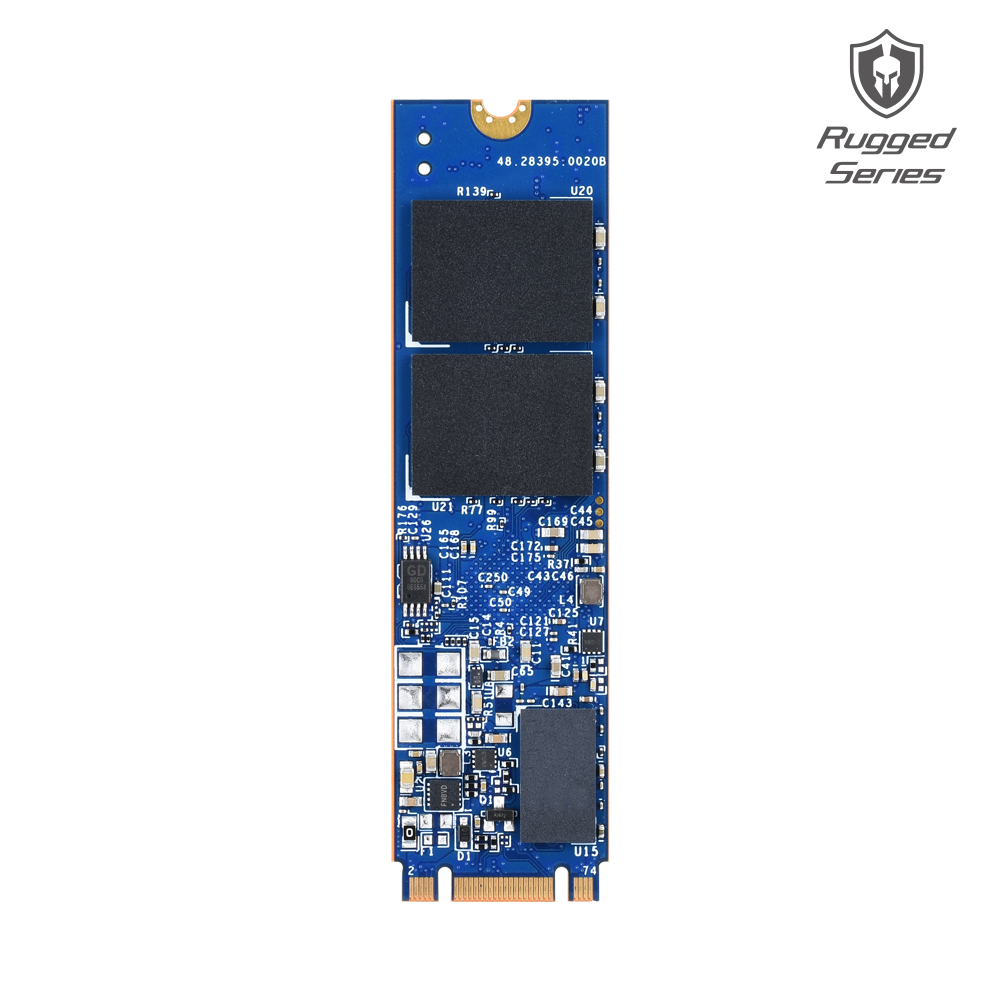

PT230-M242

-

New

SSD

PV250-M280 Single Side

-

New

-M280 正面.png)

SSD

SV240-M280 CoreSnapshot 3 Client Edition

-

New

-M280 正面.png)

SSD

SV24C-M280 CoreSnapshot 3 Cloud Edition

-

New

SSD

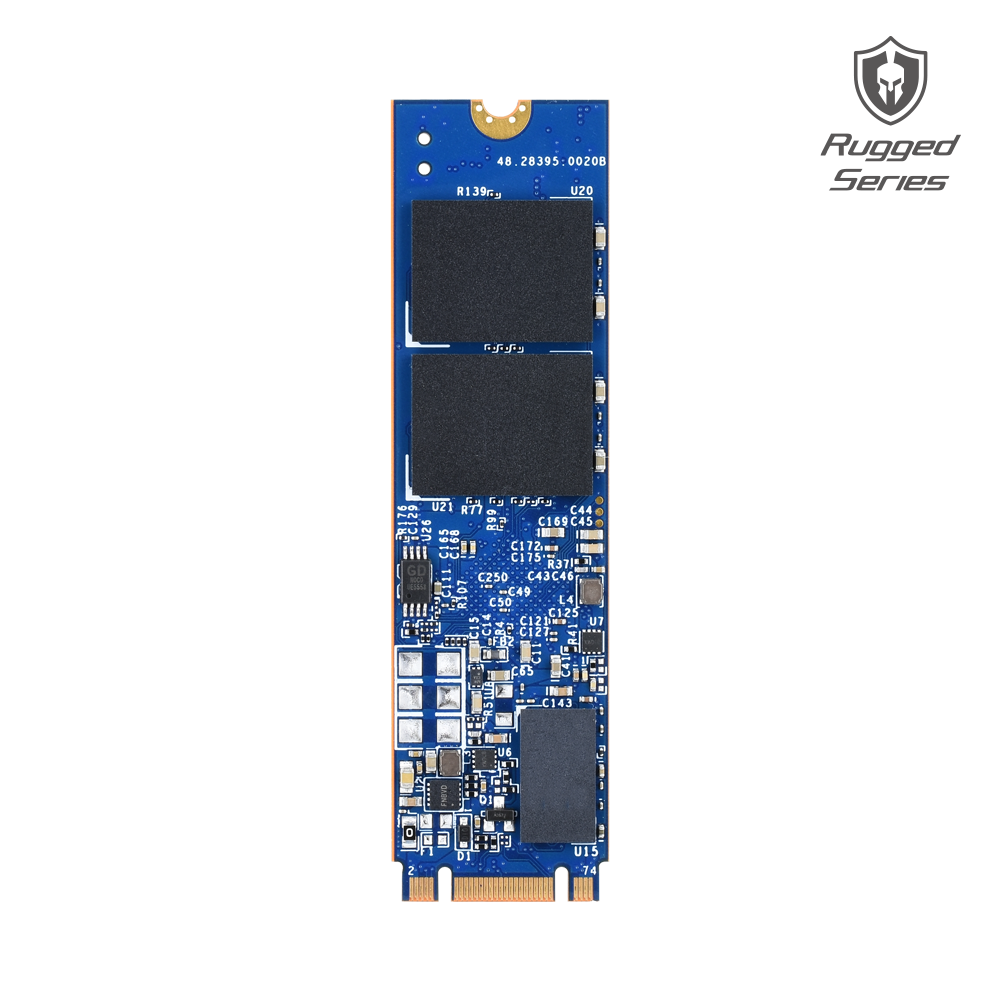

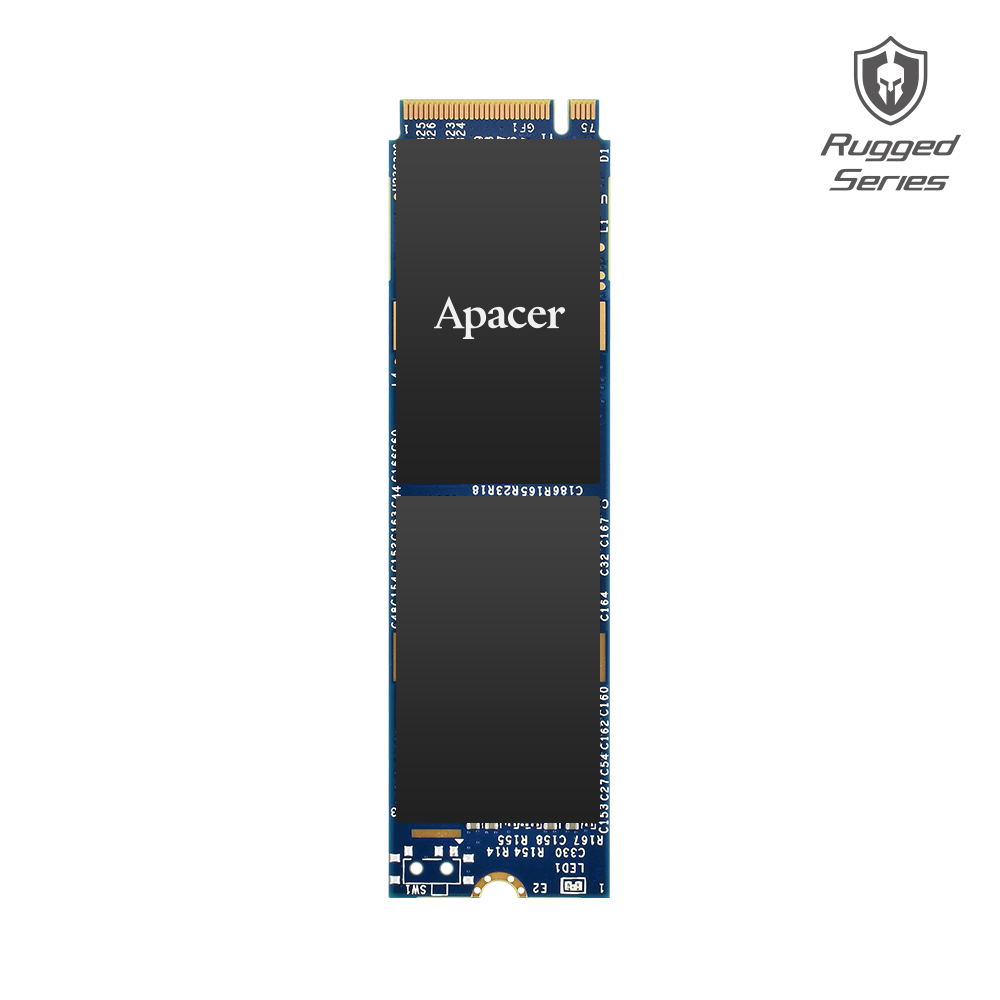

PT230-M280

-

New

SSD

PT250-M280 Single side

-

New

SSD

PT25P-M280

-

New

SSD

PT250-M280 Commercial Extended Temperature

-

New

SSD

PV250-M280 CoreSnapshot2 Client version

-

New

SSD

PV250-M242 CoreSnapshot2 Client version

-

New

SSD

PV25C-M280 CoreSnapshot2 Cloud version

-

New

(1).png)

SSD

PV250-M242

-

New

.png)

SSD

PV25P-M242

-

New

.png)

SSD

PT25P-M242

-

New

SSD

PT25P-CFX

-

New

SSD

SV25P-M242

-

New

SSD

SH25P-M280

-

New

SSD

SH25P-M242

-

New

SSD

SV250-M280 CoreRescue ASR

-

New

SSD

SV250-M242 CoreRescue ASR

-

New

SSD

PH250-M280

-

New

SSD

PH250-M242

-

New

SSD

PH930-M280

-

New

SSD

PV25P-M280

-

New

SSD

PV250-M280

-

New

SSD

SH250-M242

-

New

SSD

SH250-M280

-

New

SSD

PV910-M230

-

New

SSD

PV910-M242

-

New

SSD

ST250-M242

-

New

SSD

PV910-M280

-

New

SSD

ST250-M280

-

New

.png)

SSD

PH920-M280

-

New

.png)

SSD

PV920-M280

-

New

.png)

SSD

PV930-M280

-

New

SSD

SV240-M280

-

New

SSD

SV24P-M280

-

New

SSD

SV250-M242

-

New

SSD

SV250-M280

-

New

SSD

SV25P-M280

-

New

SSD

PV250-CFX

-

New

SSD

PV25P-CFX

-

New

SSD

SM23D-300

-

New

SSD

SM23D-M280

-

New

SSD

SM23D-25

-

New

SSD

SV24D-300

-

New

SSD

SV24D-M280

-

New

SSD

SV24D-25

-

New

SSD

SH24D-300

-

New

SSD

SH24D-M280

-

New

SSD

SH24D-25

-

New

SSD

PV22D-M280

-

New

SSD

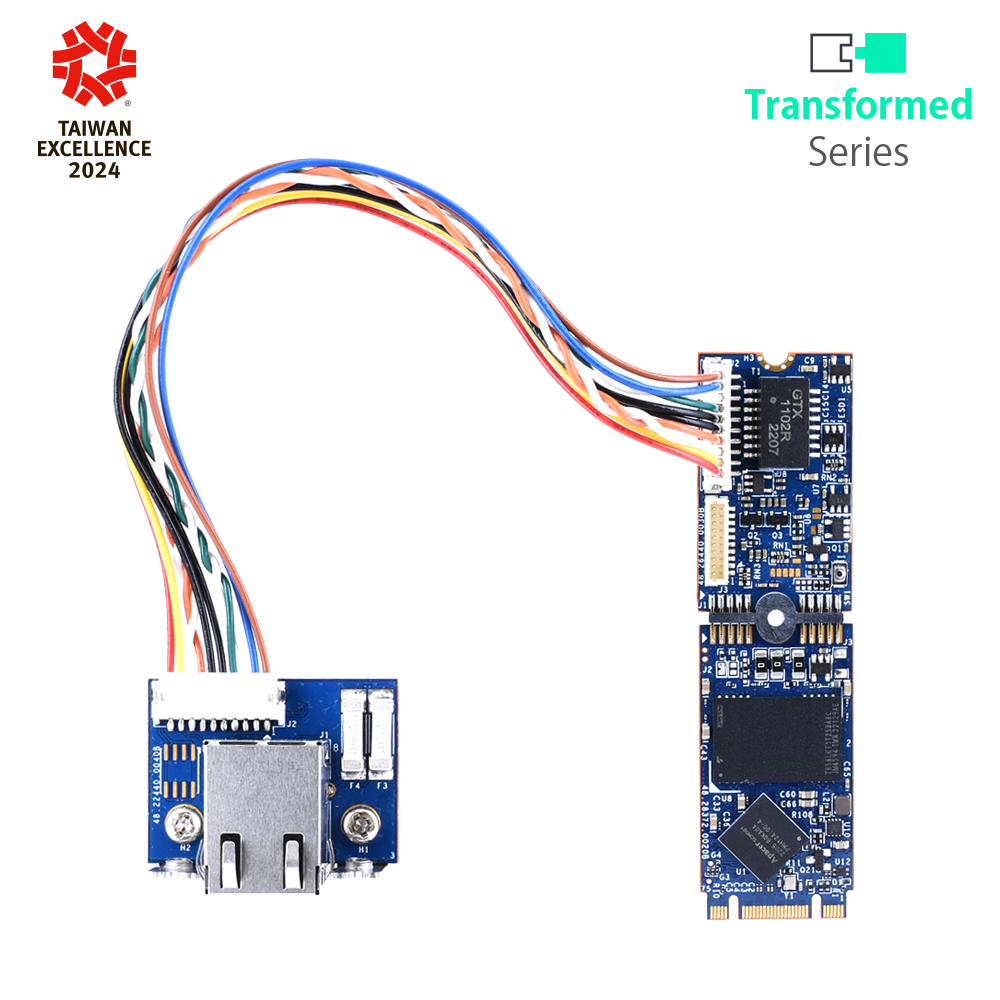

SV25T-M280 with OOB Module